The material presented in this Engineering Design Criteria Manual is intended to be used as a guide for all land development projects within the Town of Bradford West Gwillimbury. While specific design guidelines are provided herein, the Ontario Provincial Standards and Specifications supply the basis for much of the construction activity and shall be adhered to at all times unless directed otherwise by the Town and this design manual.

Prior to the commencement of the engineering design, the Developer's Consultant shall obtain the most up-to-date copy of the Town's Engineering Design Criteria Manual and familiarize themselves with the Town's requirements for engineering design. It is incumbent upon the Developer's Consulting Engineer to ensure the latest specifications are being utilized.

If you have any inquiries regarding the Engineering Design Criteria Manual please contact the Development Engineering Division. Please note that documents contain visual elements and are therefore not accessible - if you require accessibility support, please email us.

In addition to the information below, all submissions must be submitted in both a hard copy and digital copy. Digital versions may be submitted as: two (2) discs, each with a full set of PDF drawings, or a link to a FTP server containing a complete set of drawings.

Functional Servicing Report

A Functional Servicing Report (FSR) must be submitted to the Town for review and acceptance. This report must be presented in a readable, comprehensive and professional manner. The Developer shall retain a qualified Professional Engineer to prepare the FSR.

Five (5) copies of the Functional Servicing Report are to be submitted and shall contain the following information as a minimum;

(a) The Draft Plan

The Draft Plan must be in a form acceptable to the Planning Department of the Town of Bradford West

Gwillimbury. A reduced size (8½x11) copy of the draft plan as well as a full size copy (folded) shall be

included in the FSR.

(b) Contour/Drainage Plan

This plan must be at a scale of no larger than 1:1250 giving contour lines at sufficient intervals to

permit assessment of existing surface drainage patterns. This plan is to extend to the limits of the

drainage area to be served by proposed sanitary and storm sewer systems, including a topographic

survey 30m beyond the boundaries of the subdivision, or as approved by the Town. For large external

areas Contour plans at a larger scale may be provided. All elevations are to refer to Geodetic Datum.

(c) General Plan of Services

This will be a plan based on the Draft Plan and must schematically show the proposed storm and

sanitary sewer systems and their connection to existing systems. This plan is to be accompanied by

preliminary engineering calculations indicating the quantity of flows at the connection to existing

systems and/or at proposed outfalls. Consideration must be given to the whole catchment area to

ultimately be developed. Blocks and easements for drainage systems shall also be shown. Preliminary

road profiles must also be identified in the FSR.

The method of disposal of sewage shall be provided and an outline of the actual design shall be

presented, including calculations and relative size of the treatment facilities.

(d) Functional Internal Traffic Study

A Functional Internal Traffic Study is to be prepared for review prior to approval of the plan.This study

is key to properly evaluate the proposed internal road network with regard to substantiation of

proposed right-of-way widths, etc. and should be approved prior to draft plan approval. This study

would also provide information on estimated AADT for road segments, warrants for all-way stops and

traffic signals on internal intersections, analysis of on-street and off-street parking, descriptions of

opportunities for traffic calming, etc. The study should also clarify daylight triangle dimensions for the

varying hierarchy of intersections. A complete guideline for the completion of a Functional Internal

Traffic Study can be found in Appendix C.

This study shall have regard for the requirement of the Official Plan and/or the Functional Servicing

Report for the applicable Community Planning Area.

(e) Drainage/Stormwater Plan

When a natural drainage channel passes through and is affected by the subdivision, drawings must be

submitted to indicate the location and typical cross-sections of the existing channel or any proposed

changes. A preliminary stormwater management plan and report will be required by the Town to

address stormwater management planning and design issues outlined in Section C of this document

to the satisfaction of the municipality. The Town may undertake, on behalf of the Conservation

Authorities, management of digital stormwater and floodplain management models. The Developer is

to check with the Town and the local Conservation Authority to determine the current status of master

copies of these models before proceeding with storm drainage planning or design.

All proposed stormwater controls shall be in accordance with the Town, the Lake Simcoe Region

Conservation Authority or the Nottawasaga Valley Conservation Authority requirements and their

preliminary assessment and approval of the design is required.

(f) Water Systems

The FSR shall outline the proposed source and method of water distribution. For individual well

applications, a hydrogeological report shall be provided which clearly indicates the availability of

water, in compliance with Provincial guidelines and regulations.

For municipal systems, the FSR shall provide an overview of the existing water system, its capacities

and characteristics, and the needs generated by the new development. Confirmation of the water

modeling of the distribution system will be completed by the Town’s Development Engineer based on

an initial assessment and design by the Developer’s Consulting Engineer.

(g) Utilities

The FSR shall show that the proponent has had preliminary discussions with the various utility

providers and that appropriate plant is available to service the development lands.

The Developer’s Consulting Engineer is responsible to identify any and all approvals and reports required by Ontario Provincial regulations (including those that are considered Applicable Law under the Ontario Building Code), as well as the policies of the Town, County, and Conservation Authorities.

Additional reports may include studies regarding acoustic/noise issues, environmental matters, and archeological assessments.

A functional design is required prior to commencement of the final design. Prior to the commencement of the functional design, the Developer’s Consulting Engineer shall meet with the Town to discuss the requirements. The functional design shall provide all details, calculations, stormwater management/floodplain management digital models (i.e. input and output files) alternatives and recommendations necessary to evaluate the servicing of the proposed development.

In cases where the subdivision development under consideration forms part of a larger area set aside for future development, the functional report shall confirm that the servicing design does not limit the future development. The functional design shall be a definite requirement, when a subdivision is being phased and the engineering design is being undertaken for each phase separately.

Engineering submission packages are to be submitted in full to the Manager of Development Engineering. A copy of the submission correspondence (i.e. cover letters, etc.) is also to be provided to the Director of Engineering Services and the Director of Planning and Development Services.

All drawings shall be created using the Town of Bradford West Gwillimbury’s template package available for download on the Town’s website at www.townofbwg.com. See Appendix D, E, F & K for standard sheet examples and standard drawing layers. Files contained in this package are updated regularly so it is important that the consultant frequently visit the website to make sure they are using the up to date version of the template package. The package contains the following files;

- BWG COVER PAGE.dwg

- BWG INDEX PAGE.dwg

- BWG GENERAL NOTES.dwg

- BWG PLAN & PROFILE.dwg

- BWG TITLE BLOCK.dwg

- BWG STD DETAILS.dwg

- BWG UTILITY PLAN.dwg

- BWG LOT GRADING Legal.dwg

- BWG LOT GRADING Tabloid.dwg

All drawings are to be prepared in a neat and legible fashion and in general shall include the following:

- All plans shall be prepared on standard ARCH D (610mm x 914mm, 24” x 36”) sheets bond paper.

- Drawings shall be titled and sheet numbered in accordance with the Town’s Drawing Sheet Naming Convention Appendix E.

- All elevations shown on the drawings are to be of geodetic origin.

- All drawings shall be referenced to X and Y coordinates in accordance with OTM system, NAD83.

- Plan and profile drawings are to be prepared so that each street can be filed separately. The street names are to be identified on the plan portion of the drawings.

- When streets are of a length that requires more than one drawing, match lines are to be used with no overlapping of information.

- The reference drawing numbers for all intersecting streets and match lines shall be shown on all plan and profile drawings.

- Lot and Block numbers on all engineering drawings shall be the same as on the registered plan.

- A north arrow shall be referenced on all drawings.

- A key plan drawn to 1:10 000 scale shall be shown on all plan and profile drawings as well as the General Plan of Services. The area covered by the drawing shall be clearly identified.

- All engineering drawings shall be signed and stamped by the appropriate qualified professional (i.e. Professional Engineer, Landscape Architect, etc.). The drawings shall be stamped, signed and dated, prior to the issuance of drawings for tendering and signing by the Town.

- ALL DRAWINGS ARE TO BE BOUND TOGETHER AS A COMPLETE SET OF DRAWINGS AND SHALL BE DELIVERED ROLLED WITH THE PRINTED SIDE OUT.

- Exceptions and/or deviations to the published Town Engineering Design Criteria Manual shall be listed and shown in the details section of the drawing set.

All electronic (AutoCAD) drawings shall contain all infrastructure relevant to the development. The electronic files shall conform to the Universal Transverse Mercator (UTM) coordinate system (North American Datum of 1983, Zone 17N) and be tied and geo-referenced to the horizontal and vertical control monuments within the local area. The location and description with respect to the monuments shall be indicated on the drawings.

The initial engineering submission shall contain the following information:

(a) original copy of the completed Subdivision Application;

(b) a declaration from the Developer’s Consulting Engineer showing that they have been retained to

design and supervise the construction of the works of the proposed subdivision according to the

Engineering Design Criteria Manual;

(c) The table presented at the end of this section outlines the submission requirements. For second and

subsequent submissions, the original red-lined comments from the Town and any reports requiring

revision are to be resubmitted.

(d) The following engineering plans are to be prepared for each development application, as applicable:

- Cover Sheet: Showing subdivision name, application number, key plan showing the subdivision’s location relative to nearby arterial roads, Developer’s and Consultants’ information, a drawing index, Submission No. and Town File No.

- Draft M-plan: and Draft R-Plan as required.

- Draft Plan of Subdivision: Shall be the most up-to-date Draft Plan of Subdivision showing all approved redline revisions.

- General Notes Sheet: Showing the approved general notes of the Town (see Appendix F), without alteration, any other text based information not included on any other drawing and a list of design exceptions.

- General Aboveground Services Plan: Showing existing and proposed aboveground infrastructure including external works where applicable. Scale 1:1000. Including the phasing of the development as applicable.

- General Underground Services Plan: Showing existing and proposed underground infrastructure including external works where applicable. Scale 1:1000.

- Sanitary Drainage Plan: Showing existing and proposed sanitary sewers, tributary areas to each sewer including areas of future development, external drainage areas, and sewer design sheets. A separate External Sanitary Drainage Plan may be required to show large external areas. Scale 1:1000.

- Storm Drainage Plan: Showing existing ground contours to a minimum of 30m beyond the limits of development, existing and proposed storm sewers, channels, overland flow routes, 100-year ponding elevations, tributary areas to each sewer including areas of future development, external drainage areas, sewer design sheets. A separate External Storm Drainage Plan may be required to show large external areas. Scale 1:1000.

- Design Sheets (to be full size sheets, included in drawing set): Sanitary and Storm Design Sheets for the Development as outlined in this document, both digital and hard copy, computer printouts, and detail calculations for pipe strength and bedding. See Appendix H and I.

- Water Distribution System Plan: Showing existing and proposed watermains including size and type, proposed watermain elevations at all intersections and all critical junctions. The plan shall also include the internal and external demand information. Scale 1:1000.

- Grading Control Plans: Showing existing contours, existing elevations and proposed road, lot and block elevations, noise attenuation berms and fences (refer to Grading Section F for additional information required on the plan). Scale 1:500.

- Utility Coordination Plan: Showing existing and proposed aboveground and belowground utility locations, above ground service locations, road crossings, driveways (refer to Utilities Section G for additional information required on the plan). Scale 1:500.

- Traffic Management Plan: Traffic Management information to be included showing pavement markings, traffic control signage, Canada Post boxes, traffic controls, etc. Scale 1:500.

- Plan and Profile Drawings: Showing detailed alignments and profiles of the roads, sewers and watermain including pipe material, length, diameter, slope, bedding and strength classification, borehole locations, street light standard locations, restraining joints, bends on watermains. 100-year return storm hydraulic grade lines for the storm sewer shall be plotted. Service easements to be included in plan and profile drawings. These drawings are to clearly identify all relevant Town and O.P.S. Drawings not covered in the Town’s general notes (e.g., maintenance holes, safety platforms, drop structures). Horizontal Scale 1:500. Vertical Scale 1:50.

- Stormwater Management Plan: Showing the proposed stormwater management facility including the existing and proposed contours, crosssections and details of structures and other elements associated with the proposed facilities, as appropriate.

- Erosion and Sediment Control Plan: Showing temporary erosion and sediment control measures to be implemented on the site, including topsoil stockpile location and siltation control pond location, refer to Stormwater Management Facilities Section for additional information required on the plan. Should also include a schedule for the completion of the restorative works. Temporary construction access location and details are to be provided on this plan. Scale 1:1000.

- Miscellaneous Detail Plans: Other plans not specifically noted, including special details, cross-sections, acoustic and privacy fencing, retaining walls, etc.

- Standard Detail Plan: Showing the applicable Town Standards and OPSD’s, including all drawings, details to be utilized for the construction of the proposed works.

- Tree Inventory, Assessment and Preservation Plan and Details: To be prepared by a qualified arborist or landscape architect.

- Landscape and Streetscape Plans: Showing location and species of all plant material, planting details, fencing, decorative features, rehabilitation and restoration works. Include plantings for Stormwater Management Facility. Scale 1:500.

- Streetlighting Plans: Showing the underground ducts, streetlight schematic, photometric data (point plot) and details. Scale 1:500.

(e) The following engineering reports are to be prepared for each development application, all reports

and supporting documentation shall be assembled and bound, as applicable:

- Water Distribution System Analysis Report: Refer to Section D1.00 for reporting requirements.

- Stormwater Management Report & Operations and Maintenance Manual: Refer to Section C for reporting requirements.

- Hydrogeological Well Impact Report: To identify wells within a 500m radius of the site or current M.O.E requirements and identify the anticipated impact the development will have on the existing wells. Mitigating measures shall be specified, if required. Also, monitoring of the wells will be required before, during and after construction of deep municipal services.

- Geotechnical (Soils) Report: This report shall provide calculations and recommendations for pavement design, slope stability, pipe beddings, trench backfill requirements, engineered fill requirements, building foundations, retaining walls, soil corrosivity, etc., as necessary. The report is to be stamped and signed by a licensed professional engineer.

- Transportation and Traffic Impact Study: The study shall provide a summary of existing and proposed traffic volumes and conditions, time periods, evaluation of site traffic impacts, level of service (L.O.S.) calculations, mitigative measures (if required), transit operations, parking, sightlines and access requirements. The study shall also include recommendations for traffic calming, if deemed appropriate. The appropriately sized sight triangles at intersections are to be confirmed by the Consultant. The report is to be stamped and signed by a licensed professional engineer. All Transportation and Traffic Impact Studies are to be in accordance with the guidelines outlined in Appendix C.

- Noise and Vibration Report: This report shall identify sources of environmental noise and vibration under ultimate conditions and recommend mitigating measures in accordance with MOE Guidelines. Warning clauses shall be included in the report. The report is to be stamped and signed by a licensed professional engineer.

- Tree Inventory, Assessment and Preservation Plans: Plans to show inventory of all existing trees, assessment of their condition and recommendation of trees for preservation as appropriate, considering the infrastructure requirements and grading design of the proposed development. Tree Inventory shall include all trees with a diameter of 10.0cm at breast height (DBH) or greater and all trees on adjacent property within 6.0m of the property line.

At the first submission stage, a detailed cost estimate for the total cost of civil, landscape and street lighting works is to be prepared by the consulting team for purposes of calculating fees and financial securities to be held by the Town.

In addition to the information above, all submissions must be submitted in both a hard copy and a digital copy. Digital version may be submitted as: two (2) discs, each with a full set of PDF drawings, or a link to a FTP server containing a complete set of drawings.

The Town of Bradford West Gwillimbury is now a municipal partner in the MOE Transfer of Review Program. The Transfer of Review Program allows the Town as a participating municipal authority to conduct the administrative and technical review of Environmental Compliance Approvals (ECAs).

The Transfer of Review Program covers a number of works that are of a noncomplex or less environmentally sensitive nature. The agreement between the MOE and the Town as a participating municipality under the Transfer of Review Program are for the following types of works:

- Water booster pumping stations,

- Storm and sanitary sewers (except new stormwater outfalls),

- Sewage pumping stations,

- Forcemains (except those pumping directly to a sewage treatment plant),

- Stormwater management works limited to works which control stormwater quantity and/or provide basic quality control only and which discharge to either the existing stormwater management collection system, an approved stormwater management works, a ditch, a swale or a municipal drain.

As part of the second engineering submission the Developer is to submit three (3) copies of the completed Application for Environmental Compliance Approval (www.ontario.ca/environment-and-energy/environmental-approvals) and all required documents, to the Town for review.

Applications shall be completed electronically online, all of the required sections completed fully and the Application Status shown on Page 5 reads “Form Complete” and submitted in colour. Incomplete applications will be returned to the Developers Engineer. If the Town has comments related to the approval process, they will be sent to the Developers Engineer, the Town will not recommend approval until all comments are addressed.

Once the Town is satisfied with the application, a letter of recommendation for approval will be prepared by the Town for the consideration of the MOE director, and produce a draft ECA that will be submitted along with the application documentation to the MOE. The MOE will then review the application documentation and complete the process and issue the ECA to the Developer. The Developer is required to forward a copy of the MOE issued ECA to the Town.

The Municipal Drinking Water Licensing Program has now replaced the Certificate of Approval program for municipal residential drinking water systems. The Developer is no longer required to submit an application to the Ministry of the Environment for approval. The Developer is now required to submit Form-1 – Record of Watermains Authorized as a Future Alteration and all required documents, to the Town for approval.

As part of the second engineering submission, the developer is to submit three (3) copies of the completed Form 1 and three (3) copies of the Water Distribution Plan(s).

After all approvals have been received from all parties affected, the original drawings shall be submitted to the Town. These original drawings will be signed and dated by the Town and returned to the Developer’s Consulting Engineer for reproduction. Five (5) copies of the approved drawings, plus the original and four (4) reduced (11”x 17”) shall be submitted to the Town, plus;

- One complete set of digital drawings exported in AutoCAD 2007 (or latest) format, or a .dxf format where the consultant uses a CAD platform different from AutoCAD. All necessary external references should be bound to the project drawing file. The drawing should be purged of all redundant blocks, layers, etc. No object shall be on layer ‘0’, no working layers or layers with unnecessary objects shall be contained in the digital file.

- Two complete sets of digital drawings exported in PDF format (full page size).Drawings shall be submitted in complete sets on CD or DVD. Drawings to be individual PDF files labeled as per naming convention. The storage medium must be labeled with: submission date and latest revision number, municipal project number or ID, project or subdivision name, and drawing format.

Any subsequent drawing revisions must be formally submitted for approval.

If the Developer fails to enter into a Subdivision Agreement with the Town within one year of the date of the approval of the drawings by the Town, the Town reserves the right to revoke any or all approvals related to the engineering drawings.

The draft of the Subdivision Agreement will be prepared by the Town. The Developer’s Consulting Engineer shall prepare the draft schedules for the agreement where appropriate (i.e. - list of drawings, cost estimate, legal descriptions for reference plans, etc).

In order to request the preparation of the Subdivision Agreement, the following information must be submitted to the Town’s Planning and Development Services Department:

(a) A written request and all applicable fees.

(b) The name of the person and/or company and Mortgagees with whom the

Subdivision Agreement will be executed.

(c) Four copies of the Legal Description based on the Reference Plan.

(d) Four copies of the proposed final plan for registration (M-Plan) complete with all pertinent information as

required by the registry office.

(e) Four copies of the Reference Plans (R-Plans) for any easements to be granted to the Town.

(f) Two digital copies of all plans for registration, or a link to a FTP server containing one full copy of all

plans.

(g) Written confirmation from the Town’s Engineering Department that the first engineering submission has

been reviewed and comments have been provided.

(h) A detailed cost estimate of all services to be constructed. This estimate shall include:

i) detailed cost of services and landscaping;

ii) cost of underground electrical distribution system and street lighting;

iii) all miscellaneous expenditures;

iv) allowances for contingencies and engineering.

(This estimate will be used as a basis for calculation of the security to be posted for the

development.)

(i) Proposed timetable for construction of services and proposed staging plans.

(j) any required noise reports

(k) any required architectural design statements

(l) any other reports noted elsewhere or as conditions of Draft Plan approval, or as requested by the Town

prior to finalization of the Agreement.

Prior to the commencement of construction, the Developer’s Consulting Engineer shall submit the following information to the Town for approval;

(a) the names of the proposed contractor and any sub-contractors

(b) the contractor’s list of suppliers

(c) the required Letter of Credit must be posted with the Town

(d) proof of insurance in a format acceptable to the Town

(e) any other information as required by the Town or as specified in the Subdivision Agreement, or Pre

Servicing Agreement.

This section of the Town’s Engineering Design Criteria Manual is meant to be an aid for Owners, Developers, Architects or Planners when completing an Application for a Site Plan Agreement. This section will be used by Staff to ensure that the Town’s requirements have been met. The Town suggest that the Owners, Developers, Architects or Planners address each point, where applicable, in order to accelerate the approval process.

The Owner shall retain the services of a single qualified agent to administer the site plan process and design requirements, and who will coordinate other consultants/contractors on his/her behalf. A pre-consultation meeting is to be held to discuss any unique situations that may exist on the site prior to the first submission.

In addition to the information below, all submissions must be submitted in both a hard copy and digital copy. Digital versions may be submitted as: two (2) discs, each with a full set of PDF drawings, or a link to a FTP server containing a complete set of drawings.

All drawings shall be submitted with metric dimensions, be drawn in black and white, to a standard scale (1:50, 1:100, 1:200, 1:250, 1:500, etc.) and submitted on standard ARCH D (610mm x 914mm) sheets, bond paper.

In general, all drawings shall include the following information;

- Title block and revision block

- Identification of the proposed use of the site (Development Name)

- Name and address of firm preparing the Site Plan

- Name of Owner

- Municipal address and Legal Description (Reference Plan, Lot, Concession and Registered Plan Lot Number)

- Metric scale

- Key Plan indicating general location of the development in respect to the Town street network

- Bench Mark data used (geodetic) described and labeled on the drawing

- Contour lines and/or spot elevations referenced to the Benchmark

- North arrow

- Legend

- ALL DRAWINGS ARE TO BE BOUND TOGETHER AS A COMPLETE SET AND SHALL BE DELIVERED ROLLED WITH THE PRINTED SIDE OUT.

The Owner shall retain a qualified Professional Engineer to prepare all engineering drawings and to supervise the construction of all engineering services. The Consulting Engineer shall act as the Owner’s representative in all matters pertaining to the design and construction of the services in the development. A declaration from the Owner is required at the time of application showing that the Consulting Engineer

has been retained to design and supervise the construction of the proposed development. Where a question arises over the requirements for professional design, the decision of the Town shall prevail.

The following engineering documents are to be prepared for each development application, as applicable:

Seven (7) complete sets of plans for the proposed development, comprised of;

- Cover Page & Drawing Index – Showing; the Development name, Town Development number (D11-xx-xxx), Key plan showing the development location relative to the nearby arterial roads, Owner and Consultant information, Drawing Index.

- Site Plan – The Site Plan drawing shall include, but not be limited to, the following information; a Site data table; Location, dimension and setbacks of all proposed buildings and structures; Location, dimensions and setbacks of all proposed yards, landscaped open spaces, planting strips, parking area, loading spaces, driveways, walkways, sight triangles and boundary fencing; Location of all proposed light standards & wall mounted lights, signs, refuse storage areas, snow storage areas and easements; Location of sanitary sewers, watermains, storm sewers, ditches, roadways, sidewalks, road widenings, existing plantings, etc; Location of all boulevard features (i.e. curbs, landscaping, trees, utilities, etc).

- Site Servicing Plan – The Site Servicing Plan shall include, but not be limited to, the following information; Location of all existing municipal infrastructure (i.e. watermain, sanitary sewer, storm sewer, catchbasins, streetlights, traffic controls, sidewalk, signs, fences, trees or landscaping, etc.); All future local improvement works agreed to in the Site Plan Control Agreement; Location of all proposed servicing (i.e. watermain, sanitary sewer, storm sewer, catchbasins, light standards, traffic controls, etc.); All details of any service connections to the Town infrastructure including methods and materials; All utility services.

- Site Grading Plan – Where applicable, lot grading is to be in accordance with the approved overall subdivision lot grading plan. The Site Grading Plan shall include, but not be limited to the following information; spot elevations at all locations where the grade changes on the site; retaining wall information; all swale and berm information; proposed elevations on all service lids and manhole covers; elevations at all building corners, underside of footing elevation & finished first floor elevation (F.F.E.), 100 year ponding limit and access points (i.e. ramps, entrances, and loading bays); the existing elevations at 15.0m and 30.0m beyond the site limits (where possible); elevations in driveways and parking lots to show drainage patterns.

- Erosion and Sediment Control Plan - Showing temporary erosion and sediment control measures to be implemented on the site, including topsoil stockpile location and siltation control pond location, refer to Stormwater Management Facilities Section for additional information required on the plan. Temporary construction access location and details to be provided on this plan.

- Landscaping Plan - Landscape Plan shall include, but not be limited to, the following information; Location and identification of all proposed plant materials (using symbols and letters); A planting list, showing the botanical and common name, size, height, spread, spacing, condition, quantity or other pertinent information; Identification of any planting beds and existing trees to be preserved or transplanted; All proposed site furniture such as benches, bollards, tree grates, light standards, picnic tables, bike racks, etc. noted on the plan and details provided.

- Tree Inventory & Preservation Plan – The Tree Inventory/Preservation Plan shall include, but not be limited to, the following information; A detailed inventory of all existing trees, significant shrubs or hedgerows, natural features, etc., with exact surveyed locations; Location of tree protection fencing around trees and vegetation to be preserved.

- Architectural Elevations Plans - The Architectural Elevation Plans shall include, but not be limited to, the following information; the massing and conceptual design of the proposed building; the relationship of the proposed building to adjacent buildings, streets, and exterior areas; the character, scale, appearance and design features of buildings, and their sustainable design; The elevations of all sides of all main and accessory buildings, showing all roof structures (penthouses, chimneys, roof top units, vents, air conditioning, etc.) with metric measurements.

- Illumination Plan – Illumination Plans are to show the location and design of all exterior lighting, including lighting specifications. All exterior lighting needs to be adequate for the site and directed inward and down into the site. Lighting should be designed to avoid causing ambient light pollution.

- Detail Drawings & Notes

Three (3) copies of all applicable reports, including but not limited to;

- Stormwater Management Report - A Professional Engineer shall prepare a report detailing the modeling, design and features of the proposed Stormwater Management System. The Stormwater Report is to provide system performance data for the 10-year to 100-year design storms and must include scale drawings showing delineated drainage catchment areas, delineated surface pond limits for the 100-year design storms (where applicable), overland flow route and a schematic diagram reflecting the model (complex models).

- Traffic Impact Study - The purpose of the Traffic Impact Study (TIS) is to examine the impact of traffic generated by a new use at its access and at nearby intersections and interchanges, and determine necessary road improvements. The TIS will be used to support the developments internal parking lot layout and entrance locations. Impact assessment is to relate to current and future traffic volumes and the level of improvement required. The need for and content of a TIS shall be determined in consultation with the Town’s Engineering Department.

- Acoustical Study - All Industrial and commercial developments and any development adjacent to or within close proximity to residential dwellings or in any location determined to be sensitive by the Town, shall be required to conduct a noise impact analysis to demonstrate compliance to MOE guidelines.

- Any other report that may be applicable to the development, such as; Arborist Report, Servicing Design Brief, Archaeological Study, Flood Plain Analysis, Environmental Impact Study.

Installation of external works may be required within the municipal right-of-way as a result of a proposed development, the works may include items such as; the installation of municipal infrastructure (i.e. watermains, sanitary sewers, pump stations, storm sewers), traffic control devices (i.e. traffic signals), sidewalks and curbs, turning lanes, etc.

The Owner shall appoint a qualified Professional Engineer, acceptable to the Municipality, to design the external works.

The duties of the Developer’s Consulting Engineer to include, but not be limited to the following:

- prepare the designs in accordance with the Engineering Standards of the Municipality;

- prepare and furnish all required drawings in accordance with the Engineering Standards of the Municipality;

- obtain all necessary approvals from the Minister of the Environment, the local Conservation Authority, County of Simcoe and any other government or regulatory agency, as required;

- provide the field layout of the external works including the utilities and certify the quality of the required testing of the external works;

- act as the Owner's representative in all matters pertaining to the construction;

- provide coordination and scheduling to comply with the timing provisions of the Site Plan Agreement and the requirements of the Municipality, for all external works specified in the Agreement.

The “as-constructed” drawings represent amendments, changes and variances, to the approved engineering drawings, as a result of the works constructed/installed within the development, as accurately represented on all applicable drawings. “asconstructed” drawings shall be void of any previously existing features which have been altered or removed through construction. Drawing submissions shall be accompanied by revised drainage calculation design sheets which confirm the capacity of the constructed sewers.

“As-constructed” information pertaining to all underground services shall be provided prior to inspection and review, for approval of Acceptance (substantial completion) and initiation of the Maintenance Period. The “as-constructed” drawings showing all road works and servicing works shall be submitted prior to final inspections for issuance of a recommendation for Final Assumption.

The “as-constructed” revisions shall be based on a final survey of all the subdivision services and the Developer’s Consulting Engineer’s construction records. The drawings are to be accompanied by an infrastructure record sheet with all requested information relative to the services constructed. The infrastructure record sheet can be found electronically on the Town’s website or can be provided upon request. This information shall include a list of the numbers, lengths, sizes, materials, slopes, year of construction, etc. of the infrastructure items, related to the street name and/or facility, as a minimum. The infrastructure items shall include, but not be limited to:

- storm and sanitary sewers (incl. maintenance holes, catchbasins, rear lot catchbasins, headwalls, etc., including invert and top of cover elevations, sizes, distances and pipe slopes between all manholes

- watermains (including location and ties to all valve boxes, chambers, hydrants and other watermain appurtenances)

- location of all service connections to all lots and blocks

- roads and sidewalks (including lengths, widths and centerline elevations)

- traffic signs (including type, location, year installed, etc.)

- benchmarks as outlined below, Section A7.04.

All CCTV inspections of all sewer lines are required including colour video record in CD or DVD formats and a printed report.

The original drawings shall be revised to incorporate all changes and variances found during the field survey and to provide ties and additional information to readily locate all underground services.

All sewer and road grades are to be recalculated to two decimal places.

Watermain profiles are to be shown based on elevations obtained at 20m intervals.

All house numbers are to appear on all “as-constructed” drawings.

All street names, lot numbering and block identification shall be checked against the Registered Plan and corrected if necessary.

The “as-constructed” revision note shall be placed on all drawings in the revision block and dated based on when the drawings were completed.

The information on the “as-constructed” drawings may be checked by the Town at any time up to two years after final acceptance of the subdivision. If any discrepancies are found, then the drawings shall be returned to the Developer’s Consultant for rechecking and further revision.

The Developer’s Consultant shall be required to explain in writing any major difference between the design and the “as-constructed” data and to provide verification that the alteration does not adversely affect the function of the subdivision services.

Prior to the assumption of the subdivision, the Developer’s Surveyor shall establish a network of second order horizontal control monuments, as set out in “Ontario Specifications for Horizontal Control Surveys (OS 79)”, as well as a network of vertical control benchmarks, as set out in “Ontario Specifications for Vertical Control Surveys (OS 79)”.

The same monument may be used as both a horizontal and vertical control monument/benchmark. The horizontal control monuments, and the vertical control benchmarks, shall be established at approved locations to the satisfaction of the Town, using the following criteria:

- Two (2) horizontal control monuments and two (2) vertical control benchmarks for the first ten hectares (10ha) (or less) subdivided by the plan, and one (1) additional horizontal control monument and vertical control benchmark for every additional ten hectares (10ha) (or less) subdivided by the plan.

- In addition, every existing horizontal control monument and vertical control benchmark destroyed during subdivision or site plan construction must be replaced.

- The new horizontal control monuments and vertical control benchmarks (including replacements) shall be installed by an Ontario Land Surveyor. A certificate by an Ontario Land Surveyor shall be provided stating that the horizontal control monuments and vertical control benchmarks were installed as

set out by the “Ontario Specifications for Horizontal Control Surveys (OS 79)” and the “Ontario Specifications for Vertical Control Surveys (OS 79)” respectively, and confirmation from the Ministry of Natural Resources that the horizontal control monuments and vertical control benchmarks have been accepted into their Cosine Database.

-

The horizontal control monument shall be a round iron bar (0.025m x 1.22m) with brass cap or any monument approved by the “Ontario Specifications for Horizontal Control Surveys (OS 79)”. See BWG Design Standard A102.

-

The location, description and pertinent information with respect to the monuments shall be indicated on all engineering drawings and on the Town’s Survey Monument Record Sheet, Appendix G.

-

A monument is to be placed in each plan/phase of a development, to establish both vertical and horizontal control.

-

Locations to be as directed by the Town. Town confirmation required prior to construction of concrete monument.

-

Work to be 2nd order surveying, with closure between 2 known benchmarks, using double-closure method.

-

Plaques to be used as stipulated by the Town and have an identification number stamped on them as directed by the Town. Numbers are to be stamped prior to final installation.

-

Submissions to be made in the format indicated by the Town, stamped/sealed by the OLS. Supporting calculations, leveling and adjustment sheets, to be provided verifying the methodology and calculations.

-

Monumentation to be constructed on publicly owned lands in accordance with the attached detail, unless directed otherwise.

-

Horizontal control points are to be established using UTM, NAD83, Zone N17.

The final ‘As-Constructed’ drawing submission shall include all approved drawings listed in the Subdivision Agreement. Drawings which reflect ‘As-Constructed’ changes shall have ‘As-Constructed’ notation in its final revision of the title block.

The following are a list of the requirements to be met when “as-constructed” drawings are to be submitted:

- one complete set of bound “as-constructed” drawings.

- one paper and electronic (Excel spreadsheet) copy of the “as-constructed” design calculation sheets.

- one paper and electronic (Excel spreadsheet) copy of the infrastructure record sheets.

- One complete set of “as-constructed” digital drawings exported in AutoCAD 2007 (or earlier) format, or a .dxf format where the consultant uses a CAD platform different from AutoCAD. All necessary external references should be bound to the project drawing file. The drawing should be purged of all redundant blocks, layers, etc. No object shall be on layer ‘0’, no working layers or layers with unnecessary objects shall be contained in the digital file.

- Two discs, each containing a set of “as-constructed” drawings, in PDF format (full page size) or a link to a FTP server containing a complete set of PDF drawings.

Drawings and spreadsheets shall be submitted in complete sets on CD or DVD. The storage medium must be labeled with: submission date and latest revision number, municipal project number or ID, project or subdivision name, and drawing format.

The submission of the “as-constructed” drawings, in paper and digital format, to the Town must be completed before “Final Acceptance” of the subdivision will be given.

All roadways in new developments shall be classified according to the Town’s current Official Plan. The Town’s roadway classification includes the following:

- Major Arterial

- Minor Arterial

- Collector

- Local

Roadways within urban areas are to be designed and constructed to urban cross sections. Roadways servicing industrial, commercial and institutional land uses are also to be built to urban standards. Residential land uses outside of urban areas may only be constructed with rural cross sections under limited circumstances, with specific approval from the Town.

The proposed classification of all streets planned in new development areas shall be confirmed with the Town prior to the commencement of the design.

The Town will undertake the planning and design of new arterial roadways and arterial roadway widenings. The Town aims to maintain and protect the capability to achieve satisfactory capacity for the movement of people and goods, including:

- automobile movements supporting all trip purposes

- truck movements serving the downtown and employment areas

- pedestrian flows

- transit services and facilities.

All arterial to arterial road intersections will be eventually signalized. Traffic signals located between arterial road intersections will be determined by the Town. Signalized intersections will be spaced between 300m to 500m apart and the spacing will be dependent upon the arterial road and the section of arterial road being considered for signalization. In addition to permitting vehicle turning movements, traffic signals will maximize signal progression and vehicle carrying capacity while assisting other objectives of the Official Plan to be met.

Traffic signals on arterial roads will generally occur at collector roads serving continuous connections across and between concession blocks.

requirements. Local roads will be designed as standard two lane local streets permitting parking on one side.

Prior to the time of draft plan approval, the Town may require the proponent to prepare and submit two supporting traffic studies, for the Town’s approval. The first study consists of a Traffic Impact Study (TIS) which is a broad-based external transportation study that examines the property boundary conditions and

interconnections with adjacent properties (including signalization issues), assessed under existing and future conditions. The study must recommend the phasing of traffic signals and arterial road widenings to match development.

The second study consists of a Functional Internal Traffic Study (FITS) which balances appropriate urban design guidelines with a detailed assessment of internal transportation and traffic geometric design including opportunities for traffic calming, off-street or driveway parking issues, signalization warrants, roadway capacity, lane configurations, boulevard requirements (i.e., snow storage and utility corridors and buy-in from utilities), transit and pedestrian requirements, vehicle decision making criteria and intersection vehicle sight lines, medians and entrance features.

A guideline for the preparation of the traffic studies can be found in Appendix C.

The geometric road design for new roads shall adhere to the following minimum criteria table:

Table 2: Geometric Road Design

|

|

Local |

Collector |

Minor Arterial |

Major Arterial |

|

|

Design Speed (hm/hr) |

50 |

60 |

70 |

90 |

|

|

K-Sag Min. (m) |

8 |

12 |

15 |

40 |

|

|

K-Crest Min. (m) |

8 |

15 |

20 |

55 |

|

|

Minimum Centreline Radii |

90 |

115 |

250 |

400 |

|

|

Minimum Grade |

0.5% |

0.5% |

0.5% |

0.5% |

|

|

Desired Maximum Grade |

6.0% |

6.0% |

5.0% |

5.0% |

|

|

Minimum tangent length between reverse curves |

30 |

30 |

50 |

60 |

|

|

Maximum grades for through roads at intersections |

3.5% |

3.0% |

3.0% |

2.0% |

|

|

Road Width (m) |

8.0/8.5 |

9.0 |

14.0 |

15.0 |

|

|

Right-of-Way (m) [with urban design] |

20.0 |

26.0

|

30.0 |

35.0 |

|

|

Intersection Angle |

70° - 90° |

85° - 90° |

85° - 90° |

80° - 90° |

|

|

Minimum Tangent Length for intersection Approaches (from CL) (m) |

30.0 |

45.0 |

50.0 |

75.0 |

* for single-loaded roads only

All grade changes in excess of 1.0% shall be designed with a vertical curve. The minimum tangent length prior to a grade change of up to 1.0% is 6m, and between 1.0% and 1.5% is 9m. The concrete curb gutter on cul-de-sac’s and bends is to maintain a minimum grade of 0.50%.

The typical road allowance cross-section shall be designed and constructed as per the appropriate standard drawings. Details shall be provided for any special provisions required due to unique physical conditions on site or for existing or future design conditions. Such conditions include retaining walls, slope protection,

culverts, bridges or special cross fall conditions.

Laneways are to be considered for review by the Town on a case by case.

Road widening/tapering at the intersection of industrial and/or collector roads with arterial roads may be required depending on the findings and conclusions of the supporting traffic reports. The straight run and taper length for this additional pavement strip shall be determined by the Town in conjunction with the Traffic Report. In such cases, the boulevard width shall be maintained.

Property daylighting at all intersection quadrants shall be included in the road allowances in accordance with the following dimensions.

Table 3: Daylight Triangle and Curb Radii

|

Road Classification |

Intersecting |

Daylighting Triangle |

Curb Radii (m) |

|

|

Local |

Local |

5.0 |

9.0 |

|

|

Collector |

7.5 |

9.0 |

||

|

Arterial |

15 |

10.0 |

||

|

Collector |

Local |

7.5 |

9.0 |

|

|

Collector |

10.0 |

12.0 |

||

|

Arterial |

15.0 |

15.0 |

||

|

Arterial |

Local |

15.0 |

10.0 |

|

|

Collector |

15.0 |

15.0 |

||

|

Arterial |

15.0 |

15.0 |

|

Permanent cul-de-sacs are generally not permitted. Where approved, they shall be no longer than 120m. A maximum length of 150m may be permitted only where supported through a traffic study and where appropriate servicing configurations are approved by the Town.

In locations where adequate water flow requires mains connected from the two ends of the road, the pipe shall be provided through a walkway block at the end of the cul-de-sac.

The turning bulbs shall be constructed as per BWG Standard Drawing B108, minimum gutter grades of 0.5% shall be maintained along the flow line of the gutters around the bulb.

The location of utilities within the road allowance shall be as detailed in the BWG Standard Drawings for Road Cross Section Details. A Utility Coordination Plan shall be submitted to the Town for approval of the proposed utility locations.

All utility wiring is to be installed underground. Hydro transformers are to be housed in suitable enclosures and mounted on transformer pads installed at the final elevation of the adjacent ground. The location of transformer pads shall be as detailed on the Town Typical Road Cross Section Details. Telephone and Cable junction boxes may be mounted at the surface in approved standard enclosures.

In areas approved by the Town, “Trafalgar” poles may be utilized which incorporate the facilities for various utilities in the street light pole.

In general, community mail centres and/or individual super mailbox sites shall be placed in locations approved by the Town. These locations are to be indicated on the approved Utility Coordination Plan. Community mail centres shall be constructed in mini-parks, centrally and suitably located in consultation with Canada Post Corporation. The design of the community mail centre must incorporate such criteria as pedestrian safety, traffic flow and aesthetics. The Town of Bradford West Gwillimbury may require the developer to furnish the following amenities within the community mail centre:

- retaining walls

- park benches

- fencing

- litter containers

- landscaping

- pedestrian lighting

- concrete pad or interlocking stone surface

- architectural controlled kiosks

- adjacent car bays parallel to the travelled portion of the roadway.

The Developer shall be responsible for obtaining building permits when required, since some designs for these mailboxes constitute a “building” when constructed with a roof enclosure.

All details associated with the community mail centres or super mailboxes shall be identified on the Engineering Drawings and will be subject to the approval of the Town. The Developer shall be responsible for constructing community mail centres within residential subdivisions, prior to the issuance of the first building permit.

The approval of Canada Post Corporation with respect to location of community mail centres and/or site individual super mailboxes will be required prior to final approval of the Engineering Drawings

All pavement designs shall be supported by a Geotechnical Report prepared by a Professional Engineer. The report shall include results from soil testing of the existing sub-grade and recommend a pavement design required to support the anticipated traffic loading in accordance with the Transportation Association of Canada publication “A Guide to the Structural Design of Flexible and Rigid Pavements in Canada”.

The following tables provide the Town of Bradford West Gwillimbury’s minimum pavement structure requirements by road classification and driveway class. Where the minimum recommended pavement design indicated in the Geotechnical report exceeds the minimum requirements in the table below, the designer shall specify the higher strength pavement structure. Where asphaltic treatment is not warranted (e.g., gravel roads), the road structure is to be specified by a geotechnical engineer.

Table 4: Roadway Pavement Design

|

Road Classification |

O.P.S.S. Granular ‘B’ Sub-base (mm depth) |

O.P.S.S. Granular ‘A’ Base (mm depth) |

HL8 Asphalt |

HL3 Asphalt Surface (Top) Course (mm depth) |

|

|

Local |

375 |

150 |

50 |

40 |

|

|

Collector |

450 |

150 |

90 |

40 |

|

|

Arterial |

450 |

150 |

100 |

40 |

Testing and approval of all granular materials at the designated pits, prior to placement, and subsequent in-situ verification tests shall also be performed by the Developer’s Geotechnical Consultant.

Prior to the placement of asphalt pavement, the Consulting Engineer must submit to the Town for approval, the asphalt pavement mix designs.

Concrete curb and gutter conforming to OPSD 600.040 or OPSD 600.070 (two stage) shall be used on all new urban subdivision roads. Curbs are to be constructed per OPS specifications in all regards, with concrete strength to be a minimum of 30MPa at 28 days with 7% +/- 1.5% air entrainment.

A key is to be integrally formed with the curb in any location where sidewalks are immediately adjacent to the curb.

All curb and gutter is to be protected from damage from heavy equipment and vehicles.

Curb radii are to be continuous to the property line at all signalized or traffic controlled commercial, industrial or institutional entrances.

The following guidelines shall be used to determine the sidewalk construction within new subdivision developments, unless determined otherwise by the Town:

- Sidewalks shall be installed on one side of, Local and Industrial roads.

- Sidewalks shall be installed on both sides of Collector and Arterial roads.

- Sidewalks are not required on Cul-De-Sacs unless 25 or more units front onto the roadway and/or the road terminates at an amenity (i.e., park, school, commercial, open space block, etc.).

- In general, sidewalks should be located on the north and west sides of the street.

The sidewalk shall conform in details and dimensions to the current BWG Standard Drawings and shall be installed at locations as shown on the typical road cross sections.

All sidewalks to be 1.5m wide and shall be a thickness of 150mm, constructed in accordance with OPSD 310.010 and OPSD 310.030 (intersections). All concrete and works shall conform to OPSS 351. The sidewalk subgrade shall be graded to the specified tolerances and compacted to 95% Standard Proctor Density. A

150mm minimum thickness of Granular ‘A’ bedding compacted to 95% Standard Proctor Density shall be provided for all sidewalks. Concrete strength is to be a minimum of 30MPa at 28 days with 7% +/- 1.5% air entrainment.

Sidewalks to be continuous through all driveways including industrial, commercial and institutional driveways.

The minimum thickness of the concrete sidewalk when crossing industrial, commercial and institutional driveways shall be 200mm.

All sidewalks shall have a minimum cross fall of 2.0% to a maximum of 4% and no

steps are allowed.

At street intersections the curb and the sidewalk shall be depressed to meet the roadway elevations as shown on the standard drawings.

Directional grooves shall be incorporated where the slope is greater than 5% or at locations where grooves are warranted and at all intersections.

The Town requires that all concrete sidewalks be constructed as indicated on the approved Engineering Drawings, prior to preliminary acceptance.

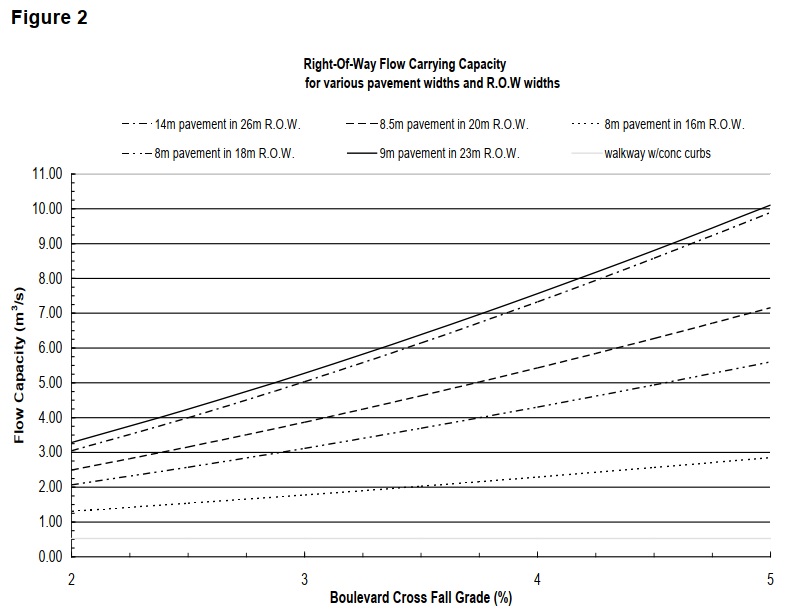

Walkways as shown on the approved draft plan are to be constructed with concrete sidewalks on a compacted base, per the standards for sidewalks and as shown on BWG Standard Drawing B111. In special cases where the major system (i.e. overland) stormwater flows are to be conveyed through walkways, a walkway with adjacent curbs as shown on BWG Standard Drawing B112 shall be used. The hydraulic capacity of the walkway as noted in Section C3.00 is not to be exceeded.

Walkways within park areas shall be located as directed by the Town and shall be constructed in accordance with the Town’s specifications (BWG Standard Drawing I102).

The developer is responsible for the grading, graveling and paving of all driveways from the curb to the face of the garage, or to the dwelling (which ever is applicable).

All driveways and parking areas in any land use area are to be fully paved.

Table 5: Driveway Pavement Design

|

Road Classification |

O.P.S.S. Granular ‘B’ Sub-base (mm depth) |

O.P.S.S. Granular ‘A’ Base (mm depth) |

HL8 Asphalt |

HL3 Asphalt Surface Course (mm depth) |

|

|

Residential |

N/A |

150 |

N/A |

50 (HL3) |

|

|

Light Industrial, |

225 |

150 |

50 |

40 |

|

|

Heavy Industrial |

300 |

150 |

75 |

40 |

The width of a single driveway shall be 3.6m, Double driveways shall be 5.5m wide the width and location of driveway depressions for commercial industrial and apartment driveways shall be detailed in accordance with OPSD 350.010, however, the maximum width shall be in accordance with applicable by-law restrictions.

Driveway depressions shall be formed in the curb according to the detail and location as per BWG Standard Drawing B109. A mechanical curb cutting machine is not permitted to saw cut driveway depressions.

All boulevard areas are to be graded to a minimum of 2% according to the details shown on the Town’s Standard Drawings to the satisfaction of the Town. The grade of the boulevard is to be constant from the back of the curb to the property line and in no case will terracing be permitted. The final grade of the sod shall match the finished grade of the top of the concrete curb and sidewalk.

All debris and construction materials shall be removed from the boulevard area upon completion of the base course asphalt and shall be maintained in a clean state until the roadway section is completed.

Topsoil that meets the requirements in section I5.02 of this document, shall be placed on all boulevard areas that are to be sodded. The minimum depth of topsoil shall be 100mm.

No. 1 Nursery Sod shall be used for all areas that are to be sodded.

Where permitted, open ditches shall be graded to the lines and grades as shown on the plan and profile drawings.

Ditch slopes shall not exceed 4:1 with a maximum depth of 1.2m below centreline grade unless otherwise approved by the Town. The minimum depth of ditches shall be 500mm below the subgrade of the road. Ditch grades shall be a minimum of 1% and a maximum of 6%, or as designed to accommodate appropriate velocities for sodded channels. Ditches with slopes less than 1% will require sub-drains to be

installed under the invert of the ditch.

Ditches are to be topsoiled with clean, weed free topsoil to a minimum depth of 100 mm. The ditch invert is to be sodded to a minimum of 2.0m wide and the balance to be seeded and mulched. When the ditch grade exceeds 6.0%, approved erosion protection shall be used.

Minimum culvert size for road crossings shall be 450mm (2.0mm thick minimum) with minimum 0.6m cover. Culverts shall be installed and bedded in accordance with OPS Specifications. All culverts require some form of end protection, being rip-rap, concrete, manufactured end sections, etc.

Driveway culverts shall be corrugated steel pipes with a minimum size of 400mm in diameter and shall be of a length to suit the driveway width. The minimum cover over driveway culverts shall be 450mm. Culverts and driveways are to be installed prior to the excavation for houses and shall include an end treatment as per the Town standard.

The proposed location and type of all street name signs, parking restrictions, traffic control signs, signalization and pavement markings shall be shown on the Traffic Control Plan and the ‘Plan and Profile’ drawings. All traffic control devices shall conform to the Ontario Traffic Manual.

Location

Street name signs shall be placed at each intersection and shall identify each street at the intersection. The location of the street name signs are shown on BWG Standard Drawing B113.

Type

All street name signs shall be manufactured and installed in accordance with the BWG Standard Drawings B114, B115 or B116. All street name signs shall be mounted on 50mm round galvanized finished steel posts 3.6m in length, and imbedded 1.20m into the ground.

Location

Traffic control and advisory signs shall be located in accordance with the Ontario Traffic Manual (OTM) as published by the Ministry of Transportation of Ontario.

All roads under the jurisdiction of the Town shall be posted with a maximum speed limit as directed by the Town.

All “No Parking” and “No Stopping” zones should be clearly identified with signs in accordance with the OTM. The Town will allow the placement of No Parking and No Stopping signs on streetlight poles to reduce clutter. The placement of signs on streetlight poles is only permitted when the appropriate spacing is achieved.

For local roads parking is generally only permitted on one side of the street. No parking zones are typically established on the side of road opposite where the sidewalk is located.

In school zones, no parking is permitted on the side of the road where the school is located and no stopping is permitted on the opposite side of the street.

A sign shall be erected at each entrance to the development stating that the roads are not assumed and shall be according to BWG Standard Drawing A101.

Type

Traffic control and advisory signs shall conform to the standards of the OTM as current at the time of installation. All signs are to be manufactured with materials as outlined in the OTM.

All regulatory/warning signs shall be mounted on galvanized steel U-flange posts (2.5kg/m) and imbedded 1.20m into the ground.

Signs must be erected at the completion of the base course asphalt and maintained by the Developer until “Final Assumption” by the Town. Temporary signs may be installed initially, however permanent signs are to be installed upon completion of all boulevard grading and sodding.

Pavement Markings for traffic control shall be provided and conform to the current standards of the OTM. All markings are to be completed with approved materials in accordance with OPSS 710.

Pavement markings shall be indicated on the plans for all stop bars, pedestrian crossings, center and lane lines, etc. as may be required for the subdivision streets. Such markings are to be shown on a Traffic Control plan.

Temporary pavement markings are to be laid immediately following the paving of base asphalt and shall be maintained as required, until top course asphalt.

Durable pavement markings shall be laid immediately following the paving of top asphalt and shall be maintained until final assumption as per OPSS 710.

Prior to the placement of asphalt after October 15th of any calendar year, the developer shall obtain specific approval from the Town on a day to day basis.

A Road Occupancy Permit is required from the Town, whenever it is necessary to perform excavations or any construction works on an existing Town right–of-way, external to the development. All work will be done in accordance with ordinances and By-laws of the Town of Bradford West Gwillimbury. The placement and

compaction of the backfill material and the restoration of the right-of-way shall be done in accordance with the standards and specifications of the Town. All road crossings shall be completed by tunneling unless explicitly approved otherwise. Any open road cut shall be backfilled with non-shrink concrete material up to the road base.

Before making detours, a traffic control plan is to be provided and permission is required from the Town. Where the road is not part of the Town road system, approval from the appropriate road authority will also be necessary. In all cases, the Fire, Police Departments, School Bus Companies and Ambulance Service must be

notified by the Developer or his Contractor.

The Town of Bradford West Gwillimbury has prepared a detailed set of design criteria and applicable parameters for the design of minor and major storm drainage facilities. These policies are to be adhered to in the production of all storm water control facilities.

The most current version of the following Ministry of the Environment (MOE), Lake Simcoe Region Conservation Authority (LSRCA) and Nottawasaga Valley Conservation Authority (NVCA) guidelines, policies and standards, apply to the design of storm drainage facilities in the Town of Bradford West Gwillimbury.

- Ministry of the Environment (i.e. Stormwater Management Planning and Design Manual, March 2003)

- Lake Simcoe Region Conservation Authority Watershed Development Policies

- NVCA Stormwater Technical Guide (December 2013)

- Technical Design Guidelines, Standards and Policies for Siltation and Erosion Control, Nottawasaga Valley Conservation Authority

- or the most up-to-date version of the above, or any new documents issued by these agencies.

Development proponents are also required to confirm design criteria and obtain approvals from any other relevant ministries or agencies (i.e. Ministry of Transportation, Ministry of Natural Resources, Department of Fisheries and Oceans, etc.). The most current version of Ontario Provincial Standard Drawings (OPSD)

shall also apply to design and construction of storm drainage facilities as determined by the Town.

The planning and design of stormwater management (SWM) facilities shall be discussed with the Town and the appropriate Conservation Authority early in the planning process and shall focus on minimizing the number of pond facilities. Master servicing plans for the various Community Planning Areas layout the general location of all planned stormwater facilities. Water quality and quantity control in

new development areas are to be provided in Town-owned municipal blocks. Proponents in these areas may consider providing on-site control (meeting Building Code requirements) however, credit for these facilities toward reducing municipal downstream municipal SWM facilities may be considered on a case by case basis.

Individual on-site SWM facilities are discouraged. In the case of infilling proposals, on-site SWM concepts may be considered by the Town in conjunction with any potential off-site storm drainage improvements.

The planning and design of each pond shall also focus on opportunities to integrate the pond with the surrounding topography and land uses. Ponds are to be created as public amenity features and are to be safe, significantly visible and accessible to the general public. Opportunities for linkages through the use of trails to larger open space, floodplain areas or other SWM facilities are to be maximized.

The planning and design of SWM works is to have full regard for riparian rights of both upstream and downstream landowners. Any change in flow rates, or water levels that would occur as a result of the development, SWM drainage areas and/or in-stream works to neighboring private properties must be adequately addressed. Written permission from affected landowners must be sought in cases where

acknowledged impacts are proposed and any governing legislation, in this regard, must be adhered to.

The level of service to be provided by the storm drainage infrastructure is listed in the following table, unless stipulated otherwise. The planning of access routes for emergency services (i.e. police, fire, and ambulance) may result in higher levels of service as determined by the Town.

Table 6: Levels of Service for Major and Minor Systems

|

Item |

Level of Service |

Comments |

|

|

Storm Sewers |

1:10 year storm |

|

|

|

Hydraulic Grade Line |

1:100 year storm |

|

|

|

Major System |

1:100 year storm |

|

|

|

Culverts |

per MTO Directive B-100 |

|

|

|

Stormwater Management |

1:100 year storm |

|

|

Table 7: Level of Service for Bridges and Culverts (per MTO Directive B-100)

|

Road Classification |

Up to 6m Span |

Over 6m Span |

|

|

Urban Arterial Road |

1:50 year |

1:100 year |

|

|

Urban Arterial Road Urban Collector Road |

1:25 year |

1:100 year |

|

|

Local Road |

1:10 year |

1:25year |

|

|

Driveways |

1:5 year |

1:10 year |

Stormwater ponds are required to meet provincial Stormwater Management (SWM) prerequisites as set out by MNR, MOE, the LSRCA and the NVCA. SWM pond locations, functions and design criteria shall be confirmed through consultation with the relevant Conservation Authority and the Town of Bradford West Gwillimbury. Where Stormwater Master Plans have been completed, the design criteria shall follow the approved Master Plan. End-of-pipe facilities are acceptable to the Town when the designs are safe, maintainable, integrated with the surrounding landscape, and aesthetically pleasing.

The Town concedes the overall design requirements to the most recent provincial direction, as is acceptable to the LSRCA and the NVCA. Exceptions to this are in circumstances that involve:

- matters of public safety and aesthetics

- maintenance requirements

- protecting the riparian rights of private landowners

- protection of municipal infrastructure and maintaining an acceptable level of protection to residents whose homes drain into a municipal drainage system

- conflicts with land use.

In these cases, the Town may invoke additional release rate stipulations and design requirements over and above those required by other agencies.

The Town requires integration of stormwater pond grading design with the surrounding landscape. The design is to consist of varied contour grading to ensure public safety, provide improved aesthetics, support of a variety of plantings and vegetation and provide passive recreational activities (i.e. walking trails, bike paths,

vistas, etc.). Safety aspects must be given special consideration. This includes identifying the use of gentle slopes in areas where passive recreation takes place, an increasing density of appropriate plantings and vegetation on steeper slopes, handrails/guardrails at headwalls and placing signs which inform of the function and potential hazards of SWM ponds.

The most current rainfall data from the Toronto-Pearson meteorological station is to be used for design of storm drainage and SWM facilities. The Intensity-Duration-Frequency curves are provided in Appendix J – Design Storms, and the equations to calculate rainfall intensity are provided in Section 3.02.

The estimation of peak design flow rates can be done using the Modified Rational Method or computer model simulation. The Modified Rational Method is typically used to design storm sewers and estimate peak flow rates from small urban areas. Its application should be limited where the time of concentration (TC) is less than approximately 30 minutes. Designers should consult the Conservation Authority requirements, where applicable, to assist in determining the most appropriate method to calculate TC.

In cases where undeveloped lands dictate the time of concentration used in Modified Rational Method design, the urban time of concentration (usually smaller) shall be used and the contributing rural area reduced to a factor of:

(TC urban / TC rural)0.5

Computer analyses are best suited to large urban areas, rural areas and designing municipal SWM facilities.

The minimum and maximum duration of design storms are 4 hours and 24 hours respectively. Hyetographs of the following design storms selected by the Town (distribution based on the Toronto-Pearson data and a 10 minute discretization) are provided in Appendix J – Design Storms:

- 24 hour SCS

- 4 hour Chicago distribution

- 24 hour Chicago distribution (where requested).

The Town, LSRCA or NVCA may request other design storm lengths and distributions for evaluation during the pre-consultation process.

The following are the A, B, C values for the Chicago Design Storms to be used in the equation:

Intensity = A / (t+B) ^C, as indicated in the following

|

Return Period |

2 Year |

5 Year |

10 Year |

25 Year |

50 Year |

100 Year |

|

|

A |

789.070 |

980.848 |

1118.790 |

1284.892 |

1405.794 |

1443.947 |

|

|

B |

6.205 |

6.013 |

6.018 |

6.008 |

6.012 |

5.273 |

|

|

C |

0.823 |

0.806 |

0.800 |

0.793 |

0.788 |

0.776 |

The Town prefers not to unnecessarily require fencing around pond blocks, but instead to allow for casual public access. Accordingly, public safety must be kept paramount in the design of SWM facilities. Table 8 (following page) summarizes pond design criteria.

The Town may elect to require fencing along any residential lot that abuts stormwater facilities. However, fencing around the perimeter of pond blocks will only be considered by the Town when reviewing submissions where there are extenuating circumstances which prevent the above requirements from being met. Specific approval will be required from the Town for consideration of fenced facilities.

Where approval for fencing stormwater ponds is given by the Town, 1.5m high black vinyl-coated fencing, posts and hardware shall be used.

Should gates in fences be requested by private homeowners, the Town requires that a clause, prepared by the Town, be registered on title of the private property absolving the Town of all liability associated with having a gate installed in a fence bordering a Town-owned SWM facility. The Town will not be responsible for legal costs incurred for registering the clause on title of the property or for the cost of the gate installation. The Town may also require construction of the fence on the private property side of the property line.

Table 8: Pond Design Criteria

|

Permanent Pool |

Maximum Slopes |

6:1 for 0.5m drop in elevation below normal water level (NWL) |

|

|